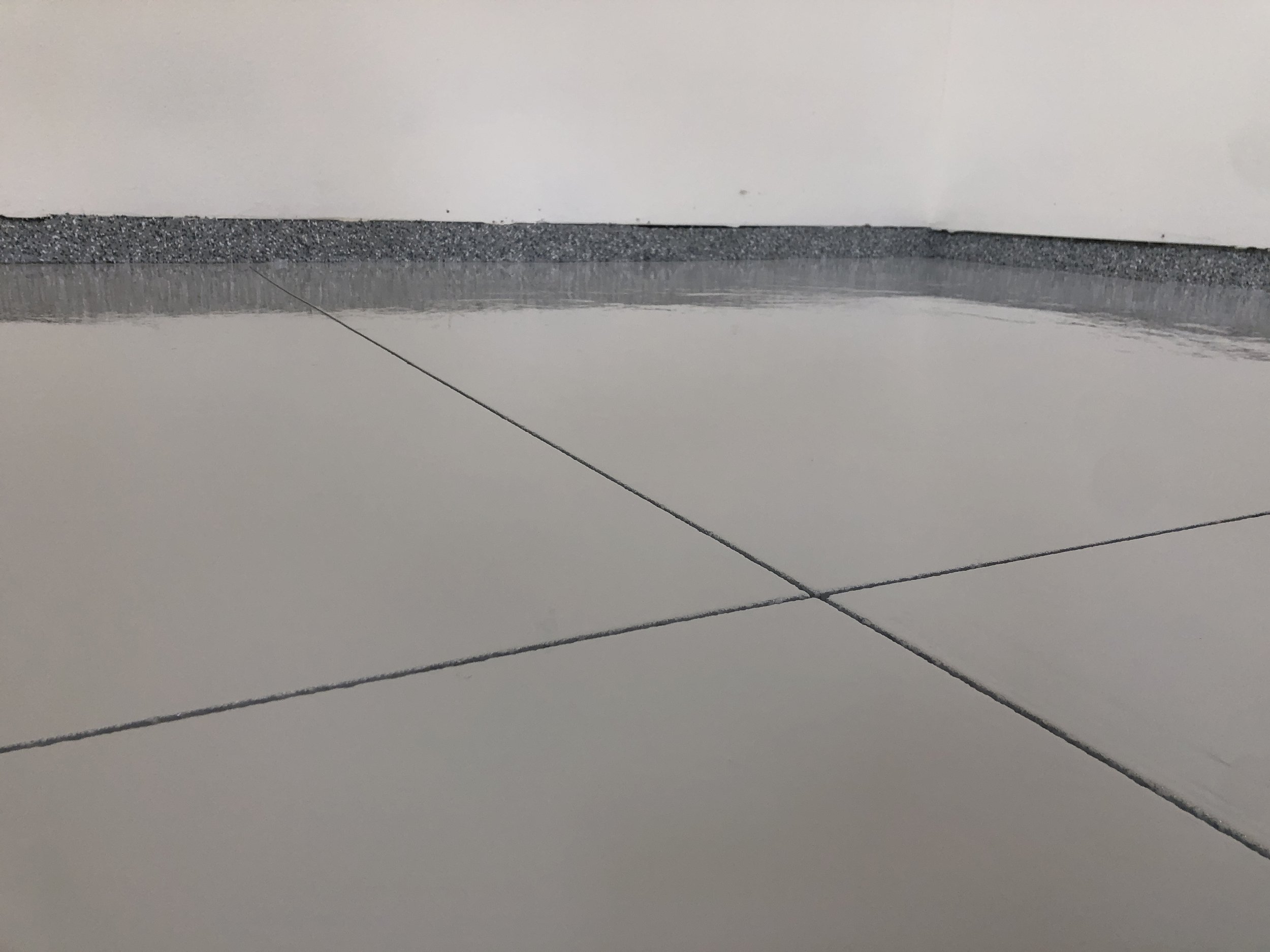

Solid Colored System

Key System Features

Epoxy Base

An epoxy primer is essential for creating a strong bond between the flooring system and the concrete substrate. Whether using a standard epoxy or a specialized moisture mitigation primer, it penetrates deep into the surface, filling pores and sealing the concrete to promote superior adhesion. This not only prevents delamination but also helps to lock down any surface contaminants and reduce outgassing, ensuring a smooth and even application for the entire system. Additionally, moisture mitigation primers protect against moisture vapor emissions, which is critical in preventing long-term flooring failures in high-moisture environments.

Build-Coat

We use a build coat between the primer and topcoat to add thickness, strength, and durability to the flooring system. Typically applied as a high-solids self-leveling epoxy or a polyaspartic coat, the build layer helps smooth out surface imperfections, increases impact and abrasion resistance, and ensures a uniform substrate for the topcoat. This additional layer not only enhances the structural integrity of the floor but also maximizes its lifespan and performance under heavy use.

Polyaspartic or Urethane Topcoat

Polyaspartic and urethane topcoats are excellent choices for finishing your flooring system because they provide superior durability, UV resistance, and chemical protection. These topcoats not only enhance the aesthetic appearance with high gloss and color stability but also offer exceptional abrasion and scratch resistance, ensuring your floor maintains its appearance even under heavy traffic. Their fast cure times and flexibility make them ideal for both industrial and commercial environments, providing a long-lasting, low-maintenance solution.